CNC Metal End Mills: The Art of Precision in Modern Machining

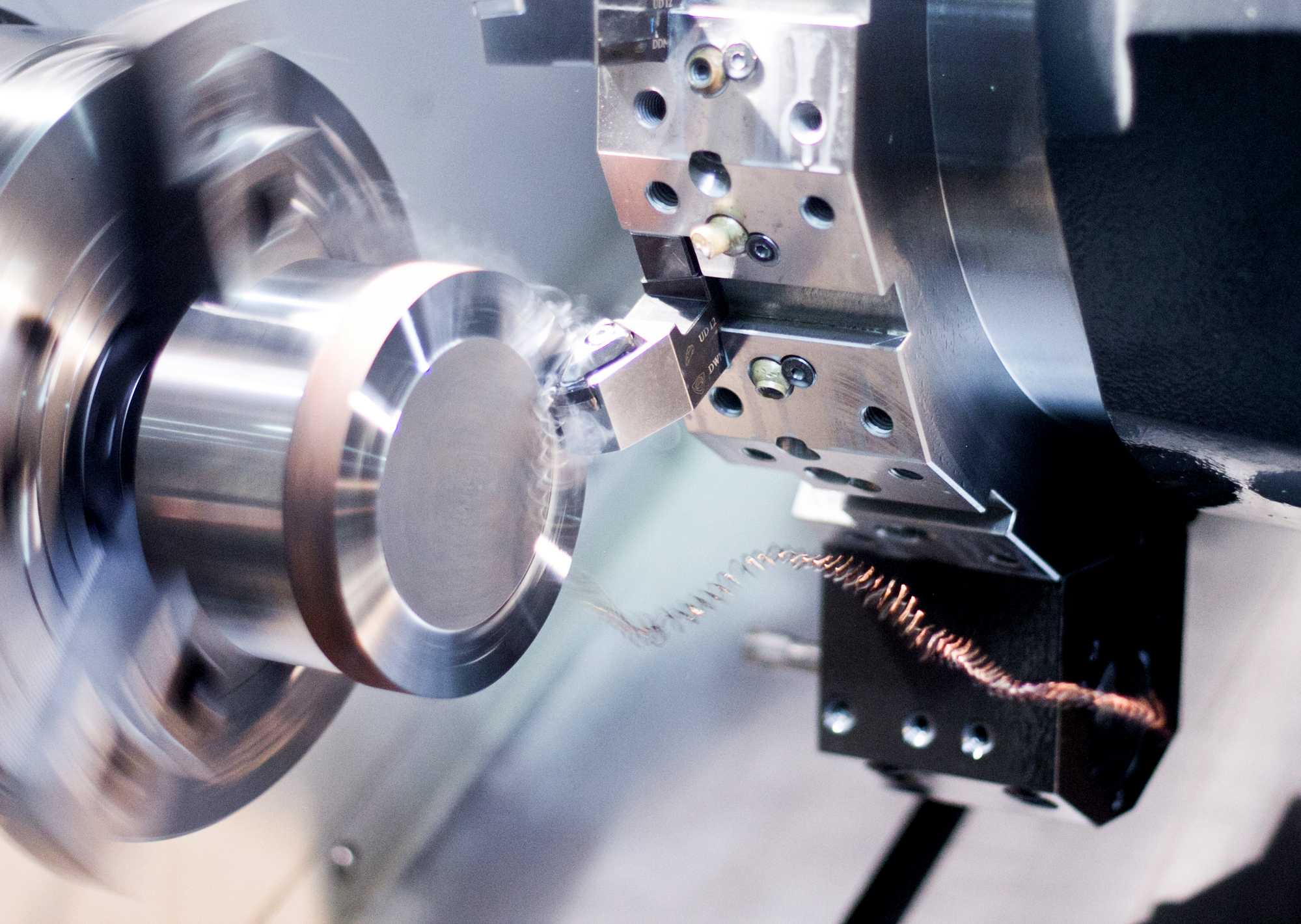

In the realm of modern machining, CNC metal end mills stand out as the epitome of precision and versatility, shaping intricate designs and components with remarkable accuracy. These specialized cutting tools, designed for use in Computer Numerical Control (CNC) machines, have transformed the manufacturing industry, allowing for complex and precise machining operations on a wide range of materials, including metals, plastics, and composites.

Precision Engineered for Superior Results

CNC metal end mills are meticulously engineered to deliver exceptional cutting performance and surface finishes. Their unique geometries and flute designs are carefully optimized to match the specific requirements of the material being machined, ensuring efficient and precise material removal while minimizing tool wear. Advanced cutting edge technologies, such as polycrystalline diamond (PCD) and cubic boron nitride (CBN) coatings, further enhance tool life and performance, allowing for extended production runs and reduced downtime.

Diverse Applications Across Industries

The versatility of CNC metal end mills is evident in their extensive use across a wide spectrum of industries, including aerospace, automotive, medical, and electronics. From intricate mold making and complex aerospace parts to delicate medical instruments and precise electronic components, these tools are instrumental in shaping a myriad of products that impact our daily lives. Their ability to machine complex geometries with high accuracy and repeatability makes them indispensable in industries demanding the utmost precision and quality.

Art and Science Intertwined: The Craftsmanship of CNC Machining

The operation of CNC metal end mills exemplifies the harmonious fusion of art and science. Skilled machinists, akin to modern-day artisans, carefully program the CNC machines to guide the tools along intricate paths, transforming raw materials into intricate and functional masterpieces. The result is a symphony of precision, where each cut, each pass of the tool, contributes to the creation of a functional work of art.

Continuous Evolution: Advancing the Frontiers of Machining

The world of CNC metal end mills is constantly evolving, driven by the relentless pursuit of innovation and technological advancement. As cutting-edge materials and manufacturing techniques emerge, tool manufacturers respond with new and improved end mill designs, enabling even more intricate machining operations and pushing the boundaries of what is possible. This continuous evolution ensures that CNC metal end mills remain at the forefront of modern machining, empowering manufacturers to create products of unparalleled quality and precision.

In conclusion, CNC metal end mills stand as a testament to human ingenuity and the ever-evolving nature of modern manufacturing. Their ability to transform raw materials into intricate and functional products with exceptional accuracy and repeatability has revolutionized industries and continues to shape the world around us. As technology advances and the demand for precision machining grows, CNC metal end mills will undoubtedly remain at the forefront, enabling the creation of products that push the boundaries of innovation and design.[Mũi Phay CNC Kim Loại: Nghệ Thuật Tinh Tế Trong Gia Công Cơ Khí Hiện Đại]

Executive Summary

This article delves into the intricate world of CNC metal milling cutters, highlighting their paramount role in shaping modern metalworking processes. With precision and efficiency at their core, these specialized tools have revolutionized the manufacturing industry, allowing for intricate designs and unparalleled accuracy. Through an in-depth exploration of their types, applications, cutting parameters, and maintenance techniques, this article aims to empower readers with a comprehensive understanding of these indispensable tools, enabling them to harness their full potential in their metalworking endeavors.

Introduction

In the realm of metalworking, precision and efficiency reign supreme. CNC metal milling cutters, with their relentless pursuit of these qualities, have emerged as the unsung heroes of modern manufacturing. These remarkable tools, guided by the unwavering precision of computer numerical control (CNC) systems, have transformed the metalworking landscape, pushing the boundaries of what was once thought possible.

Types of CNC Metal End Mills

The diverse array of CNC metal end mills reflects the vast spectrum of metalworking applications. Each type is uniquely suited to specific materials and cutting conditions, catering to the ever-evolving demands of the industry.

- High-Speed Steel End Mills:

- Renowned for their durability and affordability, these end mills excel in general-purpose applications.

- With their wide range of cutting diameters, they offer versatility for various projects.

- Their suitability for both roughing and finishing operations makes them a reliable choice for diverse tasks.

- Carbite End Mills:

- Boasting superior hardness and wear resistance, carbide end mills are ideal for tackling tough materials like stainless steel and titanium.

- Their lasting sharpness ensures longer tool life, minimizing production downtime.

- They excel in high-speed cutting operations, delivering exceptional surface finishes.

- Cobalt End Mills:

- Cobalt’s inherent toughness and heat resistance make these end mills highly effective in challenging conditions.

- Their exceptional durability allows them to withstand aggressive cutting parameters, making them suitable for heavy-duty applications.

- They excel in processing challenging materials like hardened steel and cast iron.

- Diamond End Mills:

- Renowned for their extreme hardness and cutting prowess, diamond end mills are the ultimate choice for processing ultra-hard materials.

- Their ability to maintain sharp cutting edges even under extreme conditions ensures exceptional surface finishes.

- Their suitability for intricate detailing and complex geometries makes them invaluable in mold and die making.

- PCD End Mills:

- PCD (polycrystalline diamond) end mills combine the exceptional hardness of diamond with the versatility of carbide, resulting in unmatched performance.

- They offer superior wear resistance and a longer lifespan, reducing tool changes and production downtime.

- Their ability to deliver pristine surface finishes and precise dimensions makes them ideal for precision machining applications.

Applications of CNC Metal End Mills

The versatility of CNC metal end mills extends across a wide range of industries, catering to diverse manufacturing needs. Their ability to shape and refine metal components with precision has made them indispensable tools in various sectors.

- Automotive Industry:

- High-speed steel and carbide end mills are extensively used to machine engine components, transmission parts, and suspension systems.

- Their precision and durability ensure consistent quality and performance of automotive parts.

- Aerospace Industry:

- High-hardness end mills, such as carbide and diamond, are vital for crafting intricate components like turbine blades and landing gear.

- Their ability to handle exotic materials and tight tolerances is crucial for ensuring the integrity of aircraft components.

- Medical Industry:

- Cobalt and PCD end mills are instrumental in producing medical implants and surgical instruments.

- Their biocompatibility and ability to achieve intricate geometries are essential for the production of life-saving devices.

- Electronics Industry:

- Carbide and diamond end mills are extensively used to machine printed circuit boards (PCBs) and electronic components.

- Their precision and ability to maintain sharp cutting edges are crucial for ensuring signal integrity and device performance.

- Mold and Die Making:

- Diamond and PCD end mills are essential for creating complex mold and die cavities with exceptional surface finishes.

- Their ability to precisely replicate intricate designs is vital for producing high-quality molded parts.

Cutting Parameters for CNC Metal End Mills

Optimizing cutting parameters is crucial for maximizing the performance and lifespan of CNC metal end mills. Understanding the interrelationship between various factors ensures efficient and effective metalworking operations.

- Spindle Speed:

- Selecting the appropriate spindle speed is essential for achieving the desired cutting efficiency and surface finish.

- Higher spindle speeds generally result in better surface finishes but may reduce tool life.

- Feed Rate:

- Determining the optimal feed rate is critical to prevent tool breakage and ensure proper chip formation.

- Higher feed rates can increase productivity but may compromise surface finish and tool life.

- Depth of Cut:

- Setting the appropriate depth of cut is crucial for achieving the desired material removal rate and tool life.

- Excessive depth of cut can lead to tool deflection and premature wear.

- Chip Load:

- Chip load, the thickness of the chip produced during cutting, significantly influences tool life and surface finish.

- Proper chip load selection ensures optimal cutting conditions and minimizes tool wear.

- Coolant:

- Applying coolant during cutting operations is essential for dissipating heat, reducing tool wear, and improving surface finish.

- Selecting the appropriate coolant and delivery method can significantly enhance tool performance.

Maintenance Techniques for CNC Metal End Mills

Proper maintenance of CNC metal end mills is paramount for ensuring longevity, optimal performance, and consistent quality of machined parts. Regular care and attention can significantly extend tool life and minimize production downtime.

- Cleaning:

- Regularly cleaning end mills to remove chips, debris, and coolant residue is essential for maintaining tool sharpness and preventing premature wear.

- Sharpening:

- Periodic sharpening of end mills is crucial for maintaining their cutting edge and ensuring optimal performance.

- Proper sharpening techniques and equipment are essential to prevent tool damage and premature wear.

- Coating:

- Applying specialized coatings to end mills can significantly improve their wear resistance, cutting efficiency, and lifespan.

- Common coatings include titanium nitride (TiN), titanium aluminum nitride (TiAlN), and diamond coating.

- Storage:

- Proper storage of end mills in a clean, dry place helps prevent corrosion and maintain their cutting edge.

- Storing tools in their original packaging or dedicated tool holders is recommended.

- Inspection:

- Regularly inspecting end mills for signs of wear, damage, or excessive runout is essential for preventing catastrophic tool failure and ensuring workpiece quality.

Conclusion

CNC metal end mills, with their exceptional precision, versatility, and durability, have revolutionized the metalworking industry. Their ability to shape and refine metal components with unerring accuracy has opened up new possibilities for intricate designs and complex geometries. Understanding the various types, applications, cutting parameters, and maintenance techniques of CNC metal end mills is essential for unlocking their full potential and maximizing productivity in modern manufacturing processes. By embracing the advancements brought about by these remarkable tools, manufacturers can achieve new levels of efficiency, quality, and innovation, driving the industry forward into an era of unparalleled precision and craftsmanship.

Keyword Phrase Tags:

- CNC metal end mills

- High-speed steel end mills

- Carbide end mills

- Cobalt end mills

- Diamond end mills

- PCD end mills

- Cutting parameters for CNC metal end mills

- Maintenance techniques for CNC metal end mills

- Applications of CNC metal end mills